Rigid flex PCB manufacturers produce hybrid circuit boards that combine rigid and flexible materials, enabling compact designs with reduced connectors whilst maintaining reliable electrical performance through folded or curved configurations. Leading manufacturers like OurPCB in China provide comprehensive services from design consultation and material selection through lamination, drilling, and rigorous testing using automated optical inspection and IPC-6013 compliance standards. When selecting a manufacturer, electronics engineers should verify technical expertise in stack-up design, production capabilities for both prototyping and volume runs, relevant certifications including ISO 9001 and UL, and proven experience serving demanding sectors such as medical devices, aerospace, automotive, and consumer electronics.

Key Takeaways

- Choosing a reputable rigid flex PCB manufacturer ensures your electronics combine durability with design flexibility.

- Rigid flex PCBs enable innovative layouts by integrating rigid and flexible materials, making them ideal for compact and complex devices.

- Key selection criteria for a rigid flex PCB manufacturer include technical expertise, quality assurance, and comprehensive prototyping-to-production capabilities.

- Manufacturing quality rigid flex PCBs demands precise design, advanced equipment, and strict process controls at every stage.

- Certification to industry standards like ISO 9001, UL, and IPC is essential for consistent, reliable rigid flex PCB performance across applications.

Understanding Rigid Flex PCBs

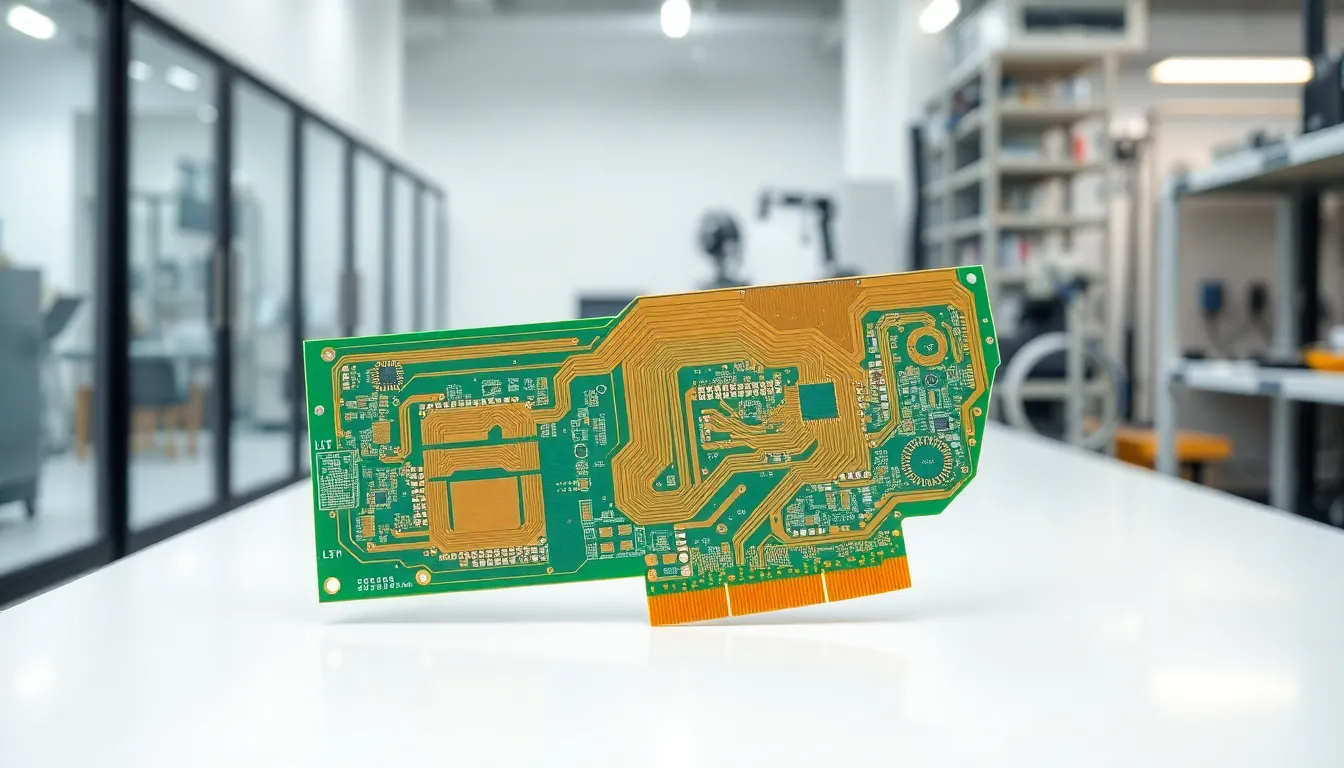

Rigid flex PCBs are circuit boards that bring together rigid panels and flexible circuits in one continuous assembly. Unlike traditional boards, they connect electronic components using a blend of sturdy areas (typically FR4) and flexible polyimide substrates. This hybrid structure allows circuits to be folded or bent while maintaining reliable performance and integrity.

In practice, rigid flex PCBs are useful for designs where space is limited or where mechanical flexibility is required. For example, they are commonly seen in wearable devices, cameras, and medical instruments, places where conventional rigid PCBs would be impractical.

OurPCB in China designs and manufactures rigid flex PCBs that meet complex layout needs without compromising signal quality or mechanical stability. Whether for prototypes or large-scale runs, working with a trusted manufacturer helps ensure that every layer, bend, and connection functions as intended.

Key Benefits of Rigid Flex PCBs

Rigid flex PCBs offer several advantages over standard rigid or flexible boards. Here are the most important benefits:

- Space and Weight Reduction: By integrating rigid and flexible sections, these boards can eliminate bulky connectors and cables, reducing weight and footprint.

- Increased Reliability: Fewer connection points mean lower risk of mechanical failures, especially in environments exposed to repeated movement or vibration.

- Improved Signal Integrity: Consistent, continuous traces between rigid and flexible zones minimize issues with cross-talk, EMI, and signal loss.

- Greater Design Freedom: Engineers have more options for product layout, allowing for creative configurations like curved or folded assemblies that would be impossible with conventional boards.

At OurPCB, these benefits are maximized by focusing on precise design and quality control at every production step. Custom solutions can be tailored to meet project requirements, whether those needs are in high-volume manufacturing or specialized prototypes.

How to Choose the Right Rigid Flex PCB Manufacturer

Selecting a rigid flex PCB manufacturer is a crucial step that influences the long-term success of your electronics project. Here are key factors to consider:

- Technical Expertise: Look for a supplier with proven experience designing and fabricating rigid flex PCBs. Depth of knowledge in stack-ups, controlled impedance, and laminate selection directly impacts final outcomes.

- Manufacturing Capability: Evaluate the facility’s equipment and scale, especially for complex or high-density interconnect (HDI) designs. OurPCB in China offers advanced production lines capable of precise multilayer builds.

- Process Transparency: Manufacturers should provide clear design guidelines, share production schedules, and support open communication throughout the project cycle.

- Prototyping and Volume Production: The right partner streamlines both quick-turn prototyping and large-scale mass production, bridging the gap as your project evolves.

- Quality Assurance: Certification, testing protocols, and traceability should all be non-negotiable. Check for documented inspections and in-house quality labs.

- Global Logistics Support: For international clients, timely delivery and robust supply chain support matter. OurPCB ships globally, making it easier for organizations to access reliable rigid flex PCB services wherever they operate.

Taking time to evaluate these elements reduces risks and aligns the finished product performance with your original design intent.

Manufacturing Process for Rigid Flex PCBs

Fabricating rigid flex PCBs involves multiple steps that unite layers of rigid and flexible materials into a single construction:

Design and Material Selection

Engineers collaborate with manufacturers like OurPCB to develop detailed Gerber files and stack-up diagrams. Material choice is critical: common options include FR4 for rigid areas and polyimide for flex zones.

Imaging and Etching

Copper is laminated onto substrates, patterns are transferred via photolithography, and then unwanted copper is etched away to form circuits.

Lamination and Bonding

Flexible and rigid layers are aligned and bonded together under heat and pressure. Special adhesives and coverlays protect flex zones, ensuring they withstand repeated movement without delamination.

Drilling and Plating

Holes for vias and component mounting are drilled, then plated with copper to connect layers electrically. This step requires strict positional accuracy, especially in fine-pitch designs.

Assembly and Final Inspection

Components are mounted, solder joints are inspected, and extensive electrical tests are performed. OurPCB uses automated optical inspection (AOI) and high-voltage testing to catch any defects before boards ship to customers.

Each manufacturing phase builds in reliability. Careful planning, experienced workforce, and up-to-date machinery are all needed to deliver consistent, high-performance rigid flex PCBs.

Quality Standards and Certifications to Consider

Assuring the quality of rigid flex PCBs depends on both manufacturing discipline and compliance with industry standards:

- ISO 9001: This general quality management certification confirms a manufacturer’s processes are well-documented and controlled.

- UL Certification: Ensures boards are manufactured with recognized safety and flammability standards in mind.

- IPC Standards (e.g., IPC-6013): IPC guidelines specifically address rigid flex construction, covering performance, acceptance criteria, and test methods.

- RoHS Compliance: Restricts hazardous substances, important for consumer electronics and medical applications.

OurPCB adheres to all major international standards, including rigorous in-house process checks. Regular audits and continuous improvement initiatives keep quality levels high, while certificates are available on request for customer peace of mind.

Manufacturers who meet these certifications are better prepared to deliver boards that are reliable, consistent, and ready for deployment in demanding applications.

Common Applications of Rigid Flex PCBs

Rigid flex PCBs are chosen for challenging environments and sophisticated devices:

- Consumer Electronics: Used in smartphones, tablets, and cameras where designers must fit electronics into compact spaces without sacrificing durability.

- Medical Devices: Chosen for surgical tools, pacemakers, and diagnostic equipment due to their light weight and reliability under movement.

- Aerospace and Defense: Perfect for avionics systems and communications equipment requiring secure, vibration-proof connections.

- Automotive: Implemented in sensors, in-dash displays, and advanced driver assistance systems (ADAS) where consistent performance is critical over years of use.

OurPCB supplies rigid flex PCBs to these demanding sectors worldwide, supporting customized builds, rigorous testing, and strict confidentiality. Specialized teams at OurPCB work directly with customers to translate complex requirements into manufacturable, cost-effective solutions.

Frequently Asked Questions about Rigid Flex PCB Manufacturers

What is a rigid flex PCB and how is it different from standard PCBs?

A rigid flex PCB combines rigid panels with flexible circuits in a single assembly. Unlike standard PCBs that are either fully rigid or flexible, rigid flex PCBs allow for folding and bending while maintaining reliability. This hybrid design reduces space and enhances durability in advanced electronics.

What are the main benefits of using a rigid flex PCB manufacturer for my project?

Partnering with a reliable rigid flex PCB manufacturer ensures optimized space usage, higher reliability, improved signal integrity, and greater design flexibility. Professional manufacturers also streamline prototyping and volume production, offering quality assurance throughout the process.

How do I choose the best rigid flex PCB manufacturer?

Look for technical expertise, advanced manufacturing capabilities, process transparency, prototyping and mass production support, quality certifications, and strong logistics. These qualities ensure your rigid flex PCBs meet performance, safety, and delivery requirements.

Which industries commonly use rigid flex PCBs?

Rigid flex PCBs are widely used in consumer electronics, medical devices, aerospace, defense, and automotive sectors. Their ability to fit complex, compact, or moving environments makes them suitable for smartphones, medical implants, avionics, and car sensors.

Are there specific certifications I should check when selecting a rigid flex PCB manufacturer?

Yes, always check for ISO 9001, UL Certification, IPC-6013 compliance, and RoHS adherence. These certifications guarantee quality management, safety, reliability, and environmental compliance in rigid flex PCB manufacturing.

What is the manufacturing process for rigid flex PCBs?

Rigid flex PCB manufacturing involves design, material selection (FR4 and polyimide), imaging, etching, lamination, drilling, plating, assembly, and rigorous inspection. Each step is crucial for ensuring the final PCB is reliable and meets design specifications.